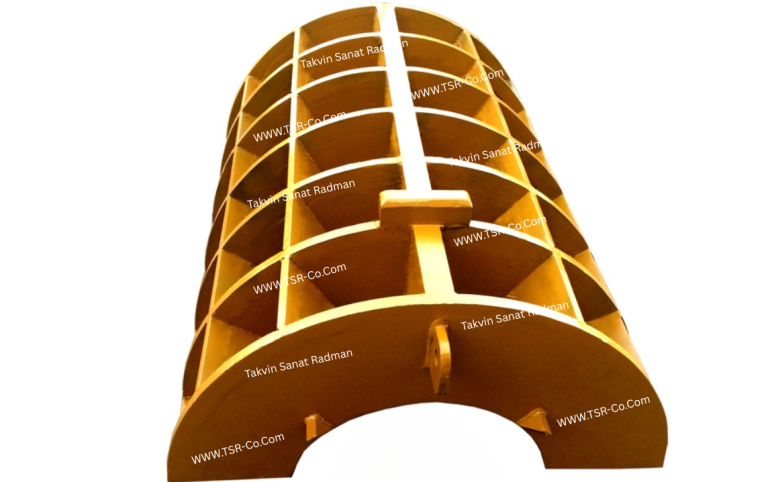

Pipe Bending Die – Comprehensive Practical Guide

Introduction:

The pipe bending die is one of the most critical components in pipe bending machines, playing the primary role in shaping pipes. These dies act like templates that give pipes their desired form.

Key Features:

- Sturdy and durable construction

- Compatibility with various pipe sizes

- Optimized design for precise bending

- Smooth, uniform surface for better work quality

Types of Bending Dies:

- Fixed dies (for standard jobs)

- Adjustable dies (for diverse projects)

- Special dies (for specific applications)

Primary Applications:

✔ Oil and gas transmission pipelines

✔ Building installations

✔ Industrial piping systems

✔ Infrastructure and construction projects

Why Die Quality Matters:

- Creates precise, uniform bends

- Prevents pipe damage

- Increases work speed and quality

- Reduces maintenance costs

Advantages of High-Quality Dies:

✅ Long service life

✅ Improved machine performance

✅ Time and cost efficiency

✅ Professional, precise results

Key Selection Considerations:

- Required pipe size and diameter

- Pipe material (steel, stainless steel, etc.)

- Desired bend angle

- Frequency of use

Takvin Sanat Radman Services:

- Free consultation

- Custom die manufacturing

- After-sales warranty and support

- Competitive pricing

FAQs:

Can one die work for all pipe sizes?

No, typically each pipe size requires its specific die.

When do dies need replacement?

Depending on usage frequency, they may require replacement after extended use.

Contact Us:

For more information and free consultation