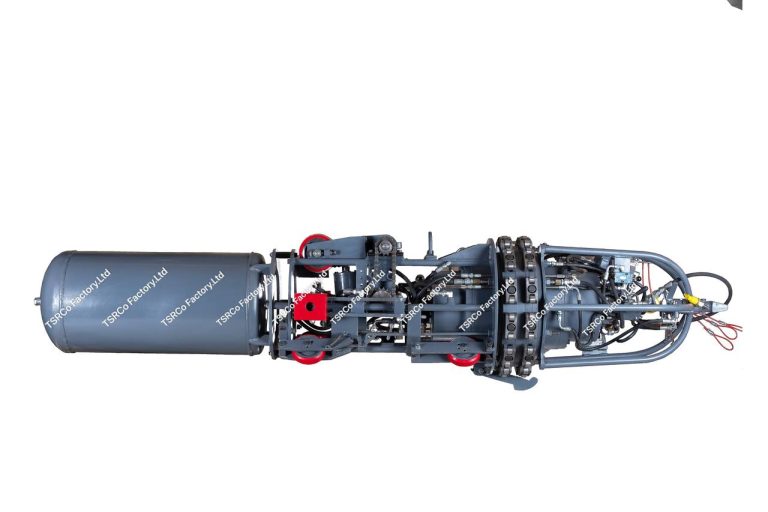

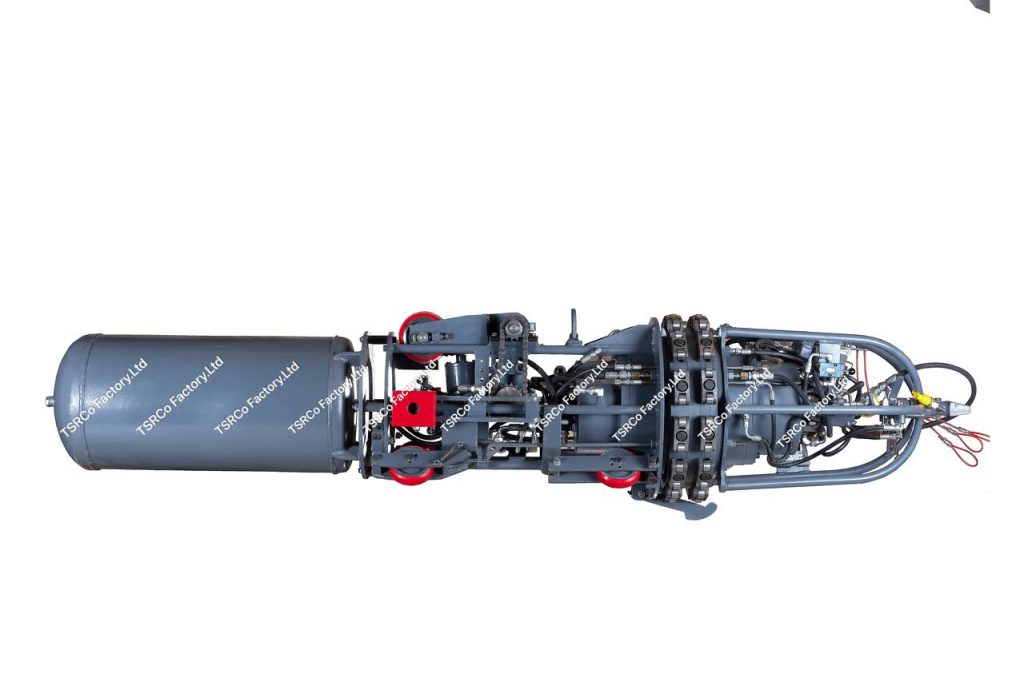

Introduction to Internal Clamps and Their Application in Oil and Gas Transmission Pipelines

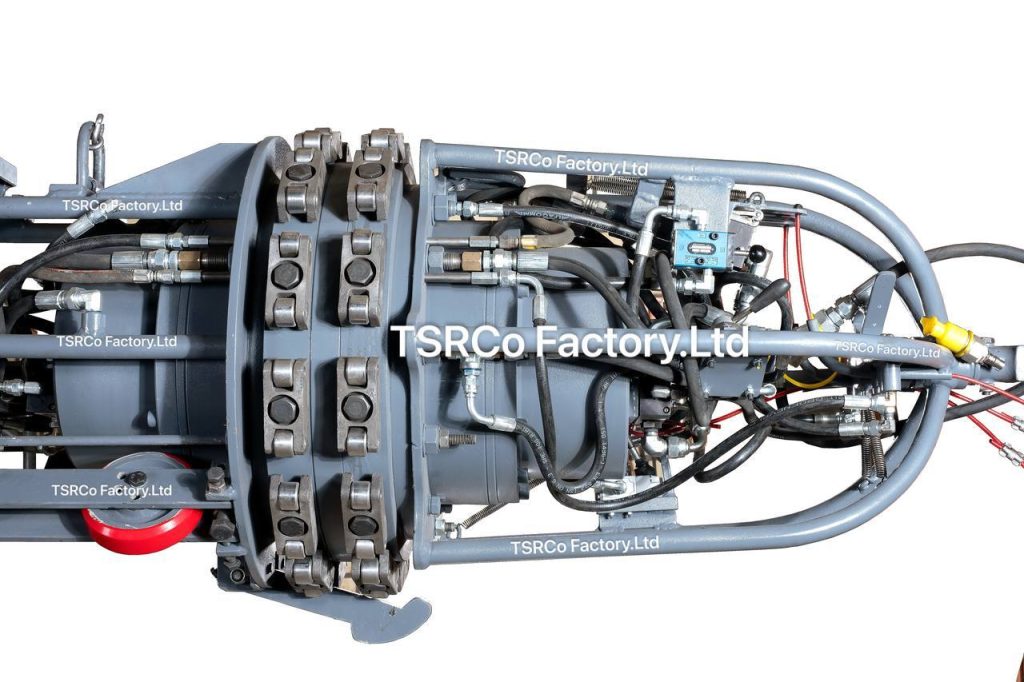

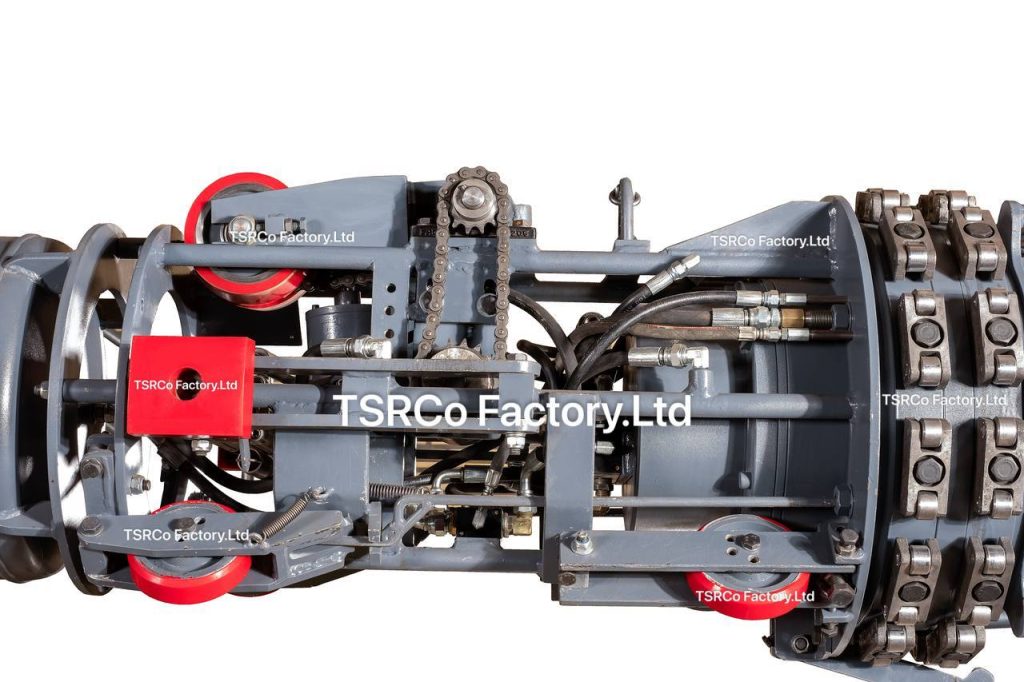

Internal clamps are one of the vital and specialized tools in the oil and gas pipeline industry, used for connecting, holding, and aligning pipes during welding and installation operations. These devices are specifically designed to ensure precision and quality in pipe joints, playing a significant role in enhancing the speed and safety of pipeline projects.

Applications of Internal Clamps in Oil and Gas Transmission Pipelines

- Precise Pipe Alignment:

- Internal clamps are placed inside the pipe to accurately align the two ends, preventing irregularities and weak points in welding.

- High-Quality Welding:

- By holding the pipes in the correct position, internal clamps enable high-quality welding that complies with international standards (such as API and ASME).

- Reduced Project Time and Costs:

- The use of internal clamps speeds up welding and pipe installation processes, thereby reducing project time and costs.

- Suitability for Harsh Conditions:

- These devices are specifically designed for use in challenging environments such as subsea pipelines, desert areas, and high-pressure zones.

Advantages of Internal Clamps

- High Precision: Ensures pipe alignment with an accuracy of less than 0.1 mm.

- Ease of Transport and Installation: Lightweight and user-friendly design for use in various environments.

- Compatibility with Various Pipes: Suitable for pipes of different diameters and thicknesses.

- Enhanced Safety: Reduces risks associated with irregularities and poor welding.

Applications in Oil and Gas Transmission Projects

Internal clamps are used in major projects such as:

- Construction of oil and gas transmission pipelines

- Refinery and petrochemical projects

- Subsea and cross-country pipelines

- Maintenance and repair of aging pipelines

Why Choose Iranian-Made Internal Clamps?

As the first manufacturer of pneumatic and hydraulic internal clamps in Iran, this company utilizes advanced technology and a skilled engineering team to produce world-class products that comply with API and ASME standards. These products not only meet domestic needs but are also competitive in international markets.